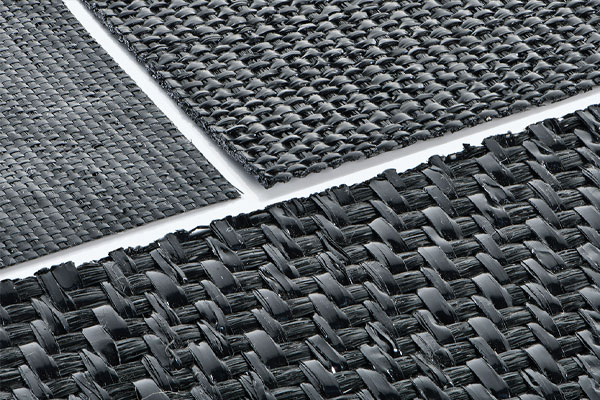

GT Braided Geotextile

GT Braided Geotextile is a knitted geotextile produced by knitting method, using pure polypropylene yarn, one in the direction of production and the other in the direction perpendicular to production.

Usage Areas and Advantages

- In structures to be built on soft and weak soils, it increases the bearing strength of the ground.

- Used as a reinforcement layer on roads due to its low elongation under high tensile force. It minimizes deformations such as uniform seating and pitting caused by vehicle wheels.

- By preventing the sub-base material from mixing with the ground, it preserves the load-bearing capacity and minimizes the material losses used in the filling.

- Prevents deterioration on the ground, especially in road constructions, by immediately absorbing some of the load and creating opposite forces at the edges of the local collapse region.

- For slope stability, especially geogrid reinforced GeoArme structures are recommended, but knitted geotextiles can also be used. This practice prevents soil loss during floods.

Packaging and Storage

It is shipped in rolls with a width of 5.0 – 5.25 m and a length of 100 m.

Materials should be stored on flat ground.

Stored products should be kept away from heat and ignition sources.