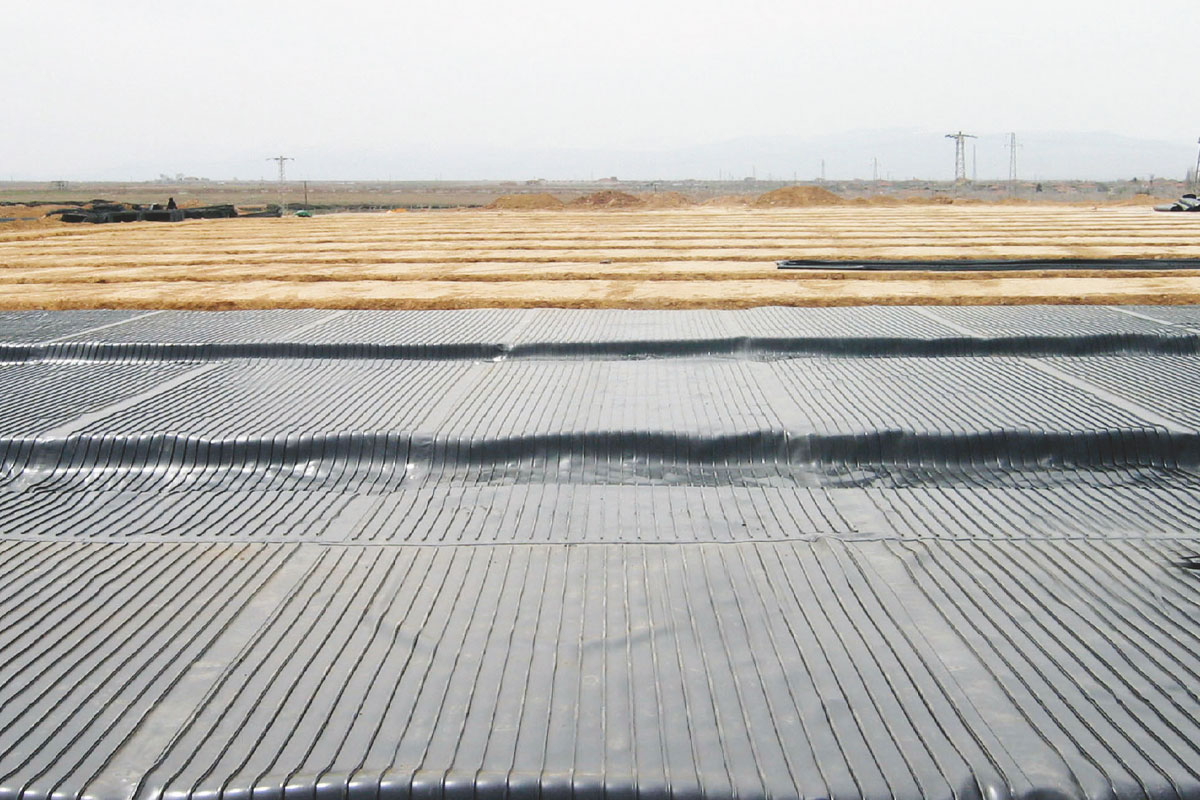

T-Grip Geomembrane

Hdpe and PVC Based Membrane

The reason why it is called T-GRIP Geomembrane is that it has T-shaped tabs that continue uninterruptedly along the entire longitudinal line. Thanks to these nails, this product locks onto the concrete it is used in very well and does not leave the concrete.

It includes general HDPE and PVC Geomembrane features. In particular, its resistance to chemicals and its aging life have been increased.

In particular, its resistance to chemicals and its aging life have been increased.

Application and Usage Areas

With the welding machine, the joints can be joined with minimum labor. Thanks to single or double row welding machines produced with the latest technology, it is possible to make a safe and controllable insulation.

- Building foundation and curtain wall insulation

- Terrace and garden terrace roofs

- Drinking water tanks

- Water reservoirs

- Light metal roofs

- Irrigation channels

- Ponds

- Metro stations

- Railway, subway and highway tunnel projects

Advantages

- Long lasting.

- It has high resistance to chemical and mechanical effects.

- The plant has root resistance.

- With its UV resistant and carrier types, it is highly resistant to external conditions.

- Products with a signal layer can be visually controlled.

- It is applied safely, easily and quickly with special welding machines.

- The tightness of the joint can be checked with double row joint welding.

Packaging and Storage

The materials are shipped in rolls with a width of 1.6 – 2.1 m and a length of 20 – 25 m.

Materials should be stored on flat ground and indoors. Stored products should be kept away from direct sunlight, heat and ignition sources. If PVC cover rolls need to be stored outdoors for a long time, they should be covered to protect them from sunlight. Smoking should not be allowed in the storage area.

Technical Specifications

| Thickness | ASTM D 5199 | mm | 0.75 – 3.00 |

|---|---|---|---|

| Density | ASTM D 1505 | g/cm³ | ≥ 0.94 |

| Current strength | ASTM D 6693 type IV | kN/m | 12-45 |

| Flow elongation | ASTM D 6693 type IV | % | ≥ 12 |

| Tear strength | ASTM D 6693 type IV | kN/m | 24-80 |

| Elongation at break | ASTM D 6693 type IV | % | ≥ 750 |

| Tear strength | ASTM D 1004 | N | 95-380 |

| Puncture strength | ASTM D 1603 | N | 280-1000 |

| Oxidation induction time (OIT) | ASTM D 3895 | min | ≥100 |