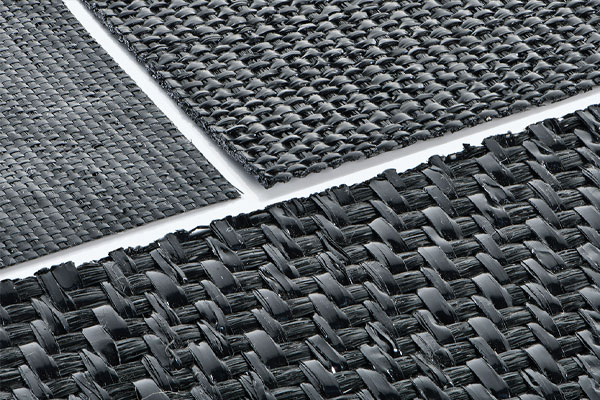

GeoBag Shore Retaining Element

GeoBag Shore Retaining Element, are special bags created by sewing high-strength polypropylene fabrics with high-strength yarns for pipeline cushioning, coastal filtration and mechanical filtration purposes. As a result of filling these bags with suitable material, water-resistant retaining elements with deformation capability are obtained.

Application and Usage Areas

- Coastal retaining structures

- In spurs and cushioning of pipelines

- For filtering water in seas or rivers

- Prevents scour on river banks

- As reinforcement in coastal dunes

- In structures with the purpose of breakwater

Advantages

- The application time is much shorter than traditional methods.

- Costs are independent of the site’s location.

- There are no problems such as finding and transporting suitable materials.

- Flexible and high strength.

- It is environmentally friendly, requires less labor and machine power.

Technical Specifications

| Dimensions | Determined by project |

| View | Pillow-shaped, black in color |

| Tensile strength | 40 kN – 120 kN |

| Extension | %14 – %18 |

| Acid and alkali resistance | High resistance |

| Water transition | Yes |

| Melting point | 160 °C |

Packaging and Storage

The bags prepared according to the project details are shipped in packages suitable for their dimensions.

GeoBag, should be stored in a packaged form, so that it is not exposed to sunlight for a long time. Products that have been opened can be reused when the packaging is properly closed.