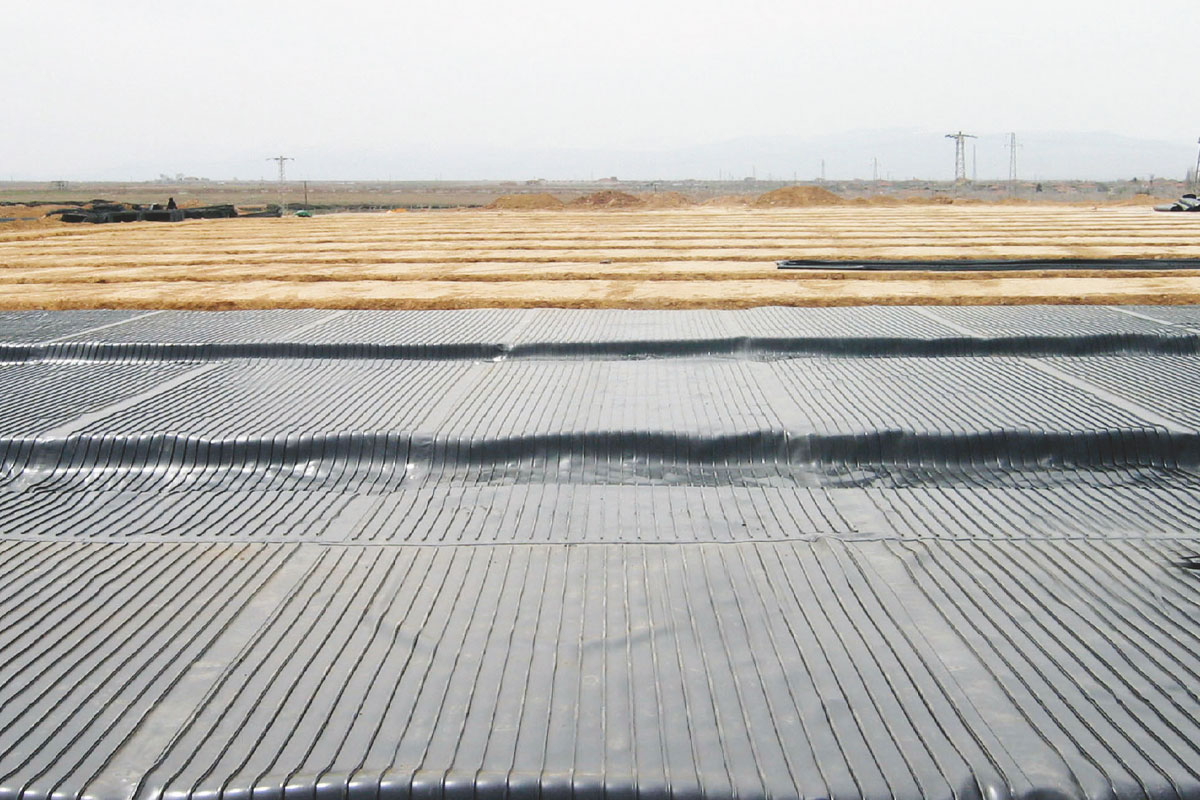

Biaxial Geogrid

Biaxial Geogrid are high-strength materials developed for bidirectional geogrid needs in various applications of civil engineering. It is produced by knitting polyester microfibres in the form of rectangles and covering them with PVC. It provides high performance thanks to a specially designed sewing method so that it can be more robust at the node points.

Application and Usage Areas

Bidirectional Geogrid is a high strength geogrid specially developed to be used in the following areas for stabilization purposes where strength is required in both directions.

- In airports runway, apron and taxiway foundations providing higher bearing capacity

- In the prevention of local settlements in applications to be made on weak ground on highways by reducing the amount of foundation and sub-base filling

- Filling works of highway widening projects

- Soil improvements to reduce the amount of ballast and sub-ballast in order to prevent potential settlements in railway applications on weak ground

- It is used in the foundations of container storage areas and industrial buildings, to increase the bearing capacity of heavy foundations and to prevent local settlements.

Advantages

- Allows the filling layer to be laid on the weak ground to be laid in a thinner thickness.

- A platform is created with the filling formed on weak soils and prevents different settlements.

- It increases the bearing capacity of the floor by being applied in layers on weak floors.

- Reduces the amount of excavation in the existing ground that is undesirable.

- It is durable, long-lasting, reliable, low cost and resistant to seismic and dynamic loads.

Product Types

- GG 20/20 P (20 kN/m / 20 kN/m)

- GG 30/30 P (30 kN/m / 30 kN/m)

- GG 40/40 P (40 kN/m / 40 kN/m)

- GG 60/60 P (60 kN/m / 60 kN/m)

- GG 80/80 P (80 kN/m / 80 kN/m)

- GG 100/100 P (100 kN/m / 100 kN/m)

- GG 150/150 P (150 kN/m / 150 kN/m)

Packaging and Storage

Bidirectional Geogrid is produced in rolls with a maximum width of 6 m and generally 100 m in length. Each roll is shipped in a UV-protected package.

It is recommended to put up to 6 rows in case of stacking, and if the roll widths are shorter (up to 2 m), it is recommended to load and store the rolls vertically.